FDM Printing Technology

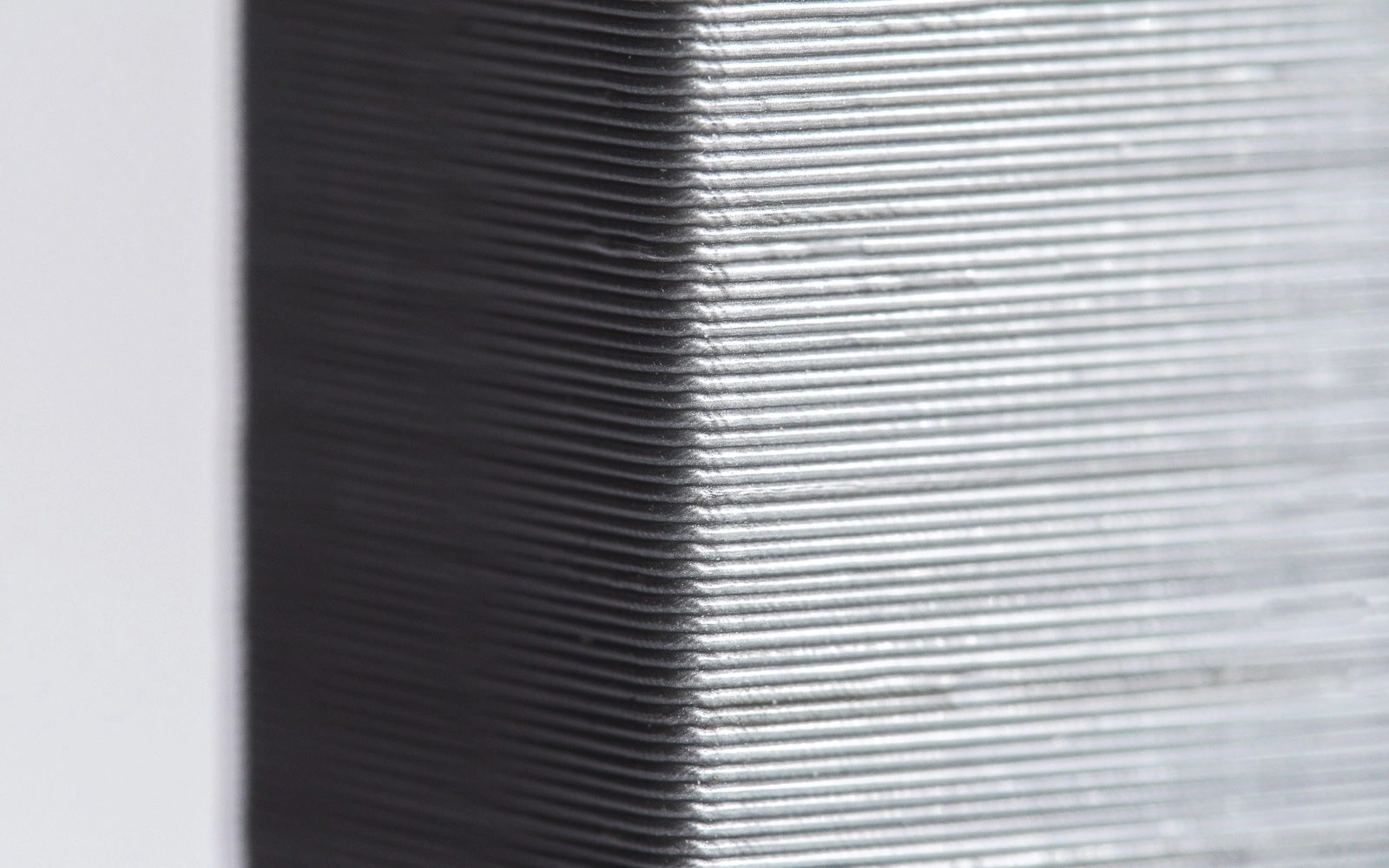

FDM (Fused Deposition Modeling) technology builds objects layer by layer by melting and extruding thermoplastic filament through a heated nozzle, creating precise, durable 3D prints.

This additive manufacturing process allows us to transform your digital designs into physical reality with excellent precision and reliability.

Advantages of FDM technology:

- Cost-effective: FDM is one of the most affordable 3D printing technologies

- Material versatility: Compatible with a wide range of thermoplastics for different applications

- Accessible: Easy to use and maintain with minimal training required

- Functional parts: Creates durable prototypes and end-use parts with good mechanical properties